We offer customers a wide variety of brushing aluminium types to suitable for multiple demands.

According to decorative needs, it can be made into straight grain, random grain, thread, corrugation and spiral pattern.

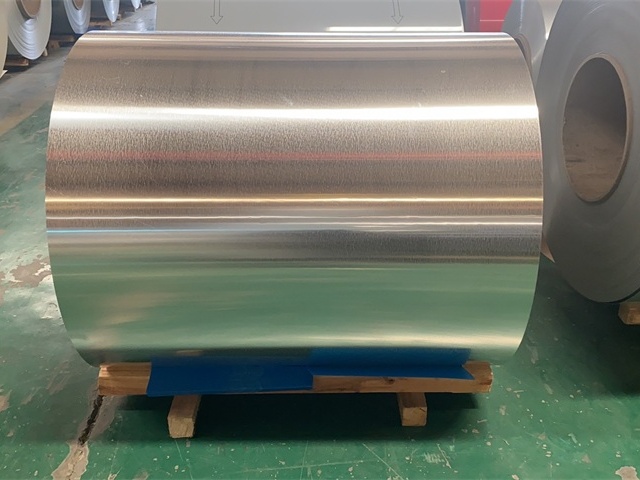

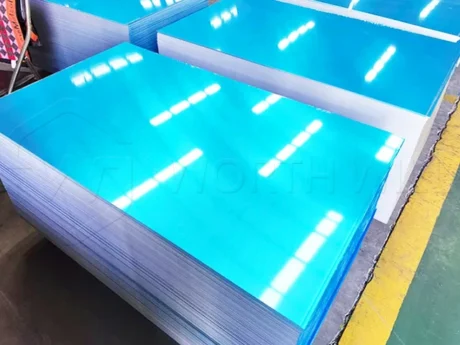

According to the shape, there is divided into aluminum sheet and aluminium coil.

Buying brushed aluminium sheet

What is brushed aluminum sheet? As a well know, it has a manufacturing process that repeatedly uses sandpaper to scrape the aluminum sheet out of the line. With the improvement of the level of science and technology, there are many inventing and using about new materials and process of aluminium.

Brushed aluminum coil

The length of the silk pattern can be adjusted.

There can be multi-directional wire drawing in the same processing.

According to demands you require, the angle between the multi-directional wire grains can be adjusted, which can greatly help customers reduce the cost.

If the aluminium alloy can meet your required specification, a customized design will be supplied. For more details, get in touch with one of our professionals online.

Brushed aluminium wrap

Brushed metal texture offers your devices a new look and definitely unique appearance. The aluminium materials plays a protective role and has coll touch precision. The materials we supply has high strength and ultra-thin tough, which is meant for adding extra wrapping to your iphone cases and cars.