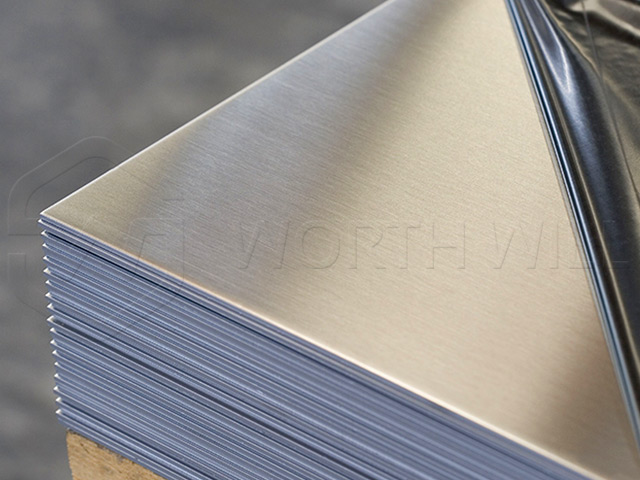

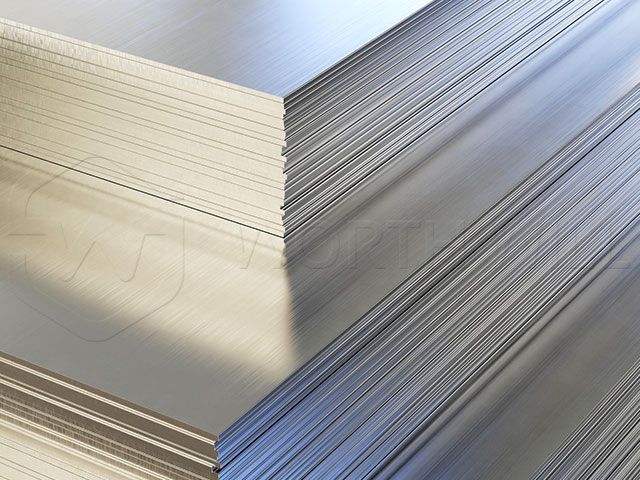

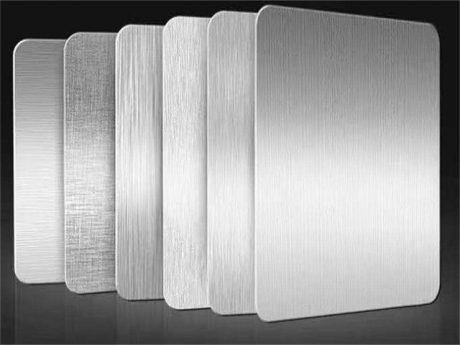

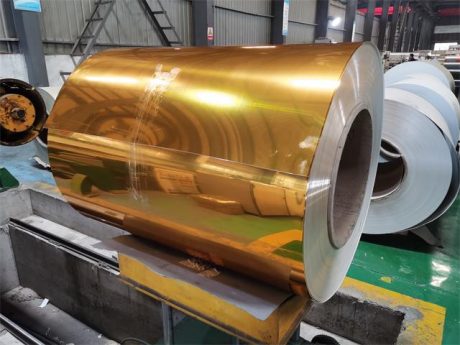

Welcome to WORTHWILL. We have a professional factory and equipment, advanced production technology, and complete service processes. 1050 aluminum plate is our excellent aluminum product, with strong durability, corrosion resistance, aesthetics, and environmental adaptability. It is widely used in many industries and is increasingly favored. If you are interested in our products, you can come and visit our factory at any time. Thank you for your interest in WORTHWILL and feel free to contact us at any time!