What is roll coating?

Roller coating uses a rotating roller as the carrier of the coating. The paint forms a certain thickness of wet film on the surface of the rotating roller, and then contacts the object during the rotation process with the help of the rotating roller. In order to achieve the goal of apply the paint on the surface of the object.

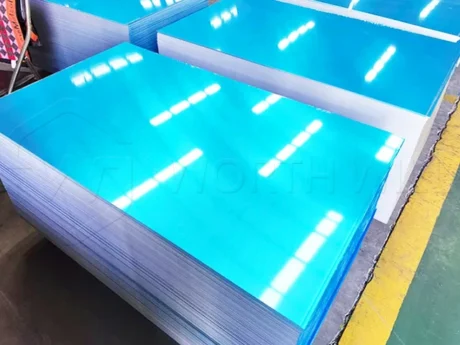

Roller coating is suitable for flat objects. It is widely used in the coating of metal plate, cloth and paper, especially suitable for metal coil coating. We usually use roller coating instead of brush coating, which can improve coating efficiency.

At present, roller coating and powder coating are the main coating method.